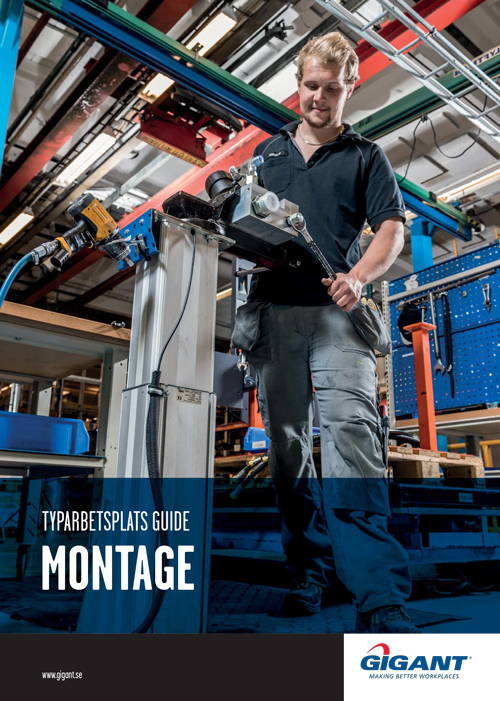

ASSEMBLY workplace

The complete solution for a better assembly workplace

The assembly workplace is a part of industry with high demands on flexibility, as the work can be carried out at a fixed workplace as well as on an assembly line or at a station in the production line. There are several benefits to improving your assembly workplace and the equipment in and around it.

Better ergonomics, greater safety and flexibility, and increased profitability are just some of them. In our workplace solution, we go through common problems and present different solutions.

The result is Type Workplace Assembly - a purchasable complete solution for those who want an assembly workplace suitable for today's modern industries.

Our approach to finding the right solution

Have you ever experienced problems with, for example, poor lighting, high noise levels or getting access to weld from all different angles? These are some of the common problems in welding workplaces around the country.

To help you solve the problems, we work based on the Gigant model - a proprietary method in three steps; analysis, solution and deployment. In step one, we define the problems and improvement opportunities that exist in your workplace, where we at Gigant can come out to you and do this on site. Based on these three steps, we develop a solution, and in step three we deploy and evaluate it.

When you buy a Typeworkplace, there are two ways to go. Either you choose a ready-made solution where much of the work is already done and can be easily adjusted to your needs.

If you have a particularly unique problem that requires a more complex solution, we also have the option of conducting a thorough analysis of your needs and then tailoring the solution.

Whichever route you choose, the result is the same: an end-to-end solution tailored to your needs that optimizes your entire workplace in one go. A simple way to increase profitability.

With over 30 years of experience, we know what works

Over a long period of time, we have accumulated knowledge about what makes a good industrial workplace. When we develop our workplace solutions, we therefore do so based on the problem areas where we have our expertise and where we know which are the most common problems, areas such as noise, ESD or load ergonomics, etc.

Our areas of competence are the expertise that drives us to a solution, which we land using the Gigant model.

For assembly, we work according to the following problem areas

Ergonomics of loading

Assembly often takes place in the field where ergonomics may not be given the same priority as in the fixed workplace, although it is just as important wherever the work takes place.

Candles

Finding the right amount of light in an assembly workplace is important. The light needs to be adjustable according to who is working, what they are working on, glare-free, etc.

Material handling

A lot of material is transported in and out of the assembly site every day. The challenge here is to make this as efficient and risk-free as possible.

Shielding

Assembly work often takes place in the middle of the business and there is usually a lot of hustle and bustle. Creating a calm workplace makes it easier to maintain concentration, makes work more efficient and reduces the risk of errors and work-related stress.

Noise

In many cases, noise in industry is a combination of many different types of sound, such as continuous noise from motors and fans, fluctuating noise from e.g. a cutting saw and impulse noise from hammer blows or similar. Therefore, screening solutions that reduce noise levels may also be necessary.

5S

On the assembly site, a variety of components are used daily and the need for a well-functioning 5S structure is therefore particularly important.

Storage

Good storage is another way to create order in the workplace. Storage should be carefully thought out to make the working day as efficient as possible

Lifting

Lifting is a common cause of many injuries in industry. Assembly workplaces handle many different parts of varying sizes, often too heavy to lift manually, and the workplace should therefore be equipped with good tools for this.

Leakage

Both the use and replenishment of chemicals are common in the assembly workplace.

ESD

Some assemblies need to be ESD-proofed and many times it is an assembly where circuit boards are handled.

Want to get started optimizing your assembly workplace?

Our installation guide explains common problems and how to solve them.