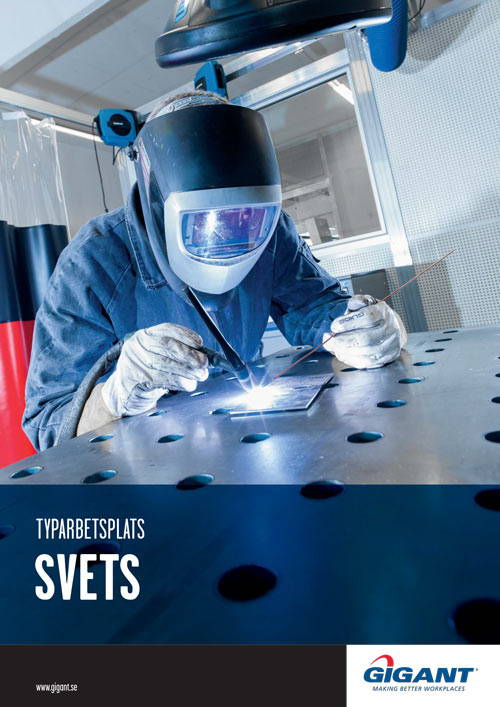

Welding workplace

a workplace with many safety requirements is THE WELDING WORKPLACE

Almost every manufacturing industry has some type of welding workplace - what is not true of all workplaces is that they are designed in the most optimal way possible. There are several benefits to optimizing your welding workplace. Better ergonomics, higher safety, less sick leave and increased profitability are just some of them. In our workplace solution, we define common problems and provide solutions.

The result is the Type Welding Workplace - a purchasable complete solution for those who want a welding workplace suitable for today's modernized industry.

Our approach to finding the right solution

Have you ever experienced problems with, for example, poor lighting, high noise levels or getting access to weld from all different angles? These are some of the common problems in welding workplaces around the country.

To help you solve the problems, we work based on the Gigant model - a proprietary method in three steps; analysis, solution and deployment. In step one, we define the problems and improvement opportunities that exist in your workplace, where we at Gigant can come out to you and do this on site. Based on these three steps, we develop a solution, and in step three we deploy and evaluate it.

When you buy a Typeworkplace, there are two ways to go. Either you choose a ready-made solution where much of the work is already done and can be easily adjusted to your needs.

If you have a particularly unique problem that requires a more complex solution, we also have the option of conducting a thorough analysis of your needs and then tailoring the solution.

Whichever route you choose, the result is the same: an end-to-end solution tailored to your needs that optimizes your entire workplace in one go. A simple way to increase profitability.

With over 30 years of experience, we know what works

Over a long period of time, we have accumulated knowledge about what makes a good industrial workplace. When we develop our workplace solutions, we therefore do so based on the problem areas where we have our expertise and where we know which are the most common problems, areas such as noise, ESD or load ergonomics, etc.

Our areas of competence are the expertise that drives us to a solution, which we land using the Gigant model.

in welding, we work to solve the following problem areas

Ergonomics of loading

On a welding site, it is not uncommon to work in awkward positions to access and weld at all heights and angles. This makes ergonomics particularly important.

Candles

Both sufficient light and the right kind of placement are needed to ensure the well-being of employees and to avoid errors.

Lifting

Welding workplaces often handle slightly heavier steel structures to be welded. This requires good tools and methods to handle these lifts.

Noise

Like many other parts of an industry, high noise levels can occur in a welding workplace. There are several solutions to create a better and quieter working environment.

5S

Order and tidiness are extremely important in a welding workplace as the risk of fire is high.

ESD

Both flammable and explosive goods can be present in a welding workplace. It is important to handle them properly.

Want to get started optimizing your welding workplace?

In our welding guide, we go through common problems and how to solve them.